Aircraft cable

Aircraft cable, also known as wire rope, is a type of strong, flexible cable made of intertwined wire strands. It is commonly used in the aerospace industry for a variety of applications, including securing large cargo or suspending aircraft components.

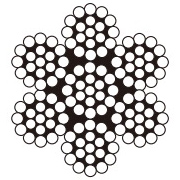

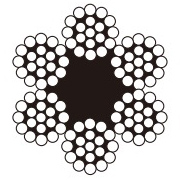

The construction of aircraft cable typically involves a series of wire strands that are twisted together to create a sturdy, yet flexible, rope-like structure. The wires are usually made of high-strength materials such as stainless steel, carbon steel, or galvanized steel, all of which provide excellent resistance to corrosion and other environmental factors.

One of the key advantages of aircraft cable is its ability to support heavy loads while remaining lightweight and easy to handle. This makes it an ideal choice for use in aerospace applications where weight is a critical factor. In addition, the flexibility of the cable allows it to conform to complex shapes and angles, making it versatile and adaptable to a wide range of applications.

When choosing an aircraft cable, several factors should be considered, including the intended use, the required strength and durability, and the environmental conditions that the cable will be exposed to. Proper training and handling techniques are also important to ensure that the cable is used safely and effectively.

Overall, aircraft cable is a critical component in many aerospace applications, providing a strong and reliable solution for supporting heavy loads or suspending critical components. Its unique construction and properties make it a valuable tool for any aerospace project where reliability and safety are top priorities.

MIL-DTL-83420P

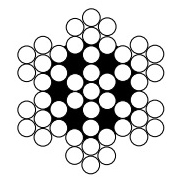

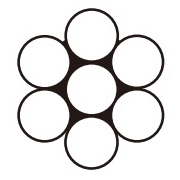

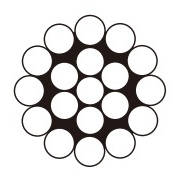

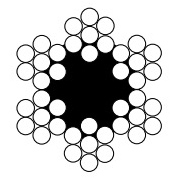

Construction, physical properties of type I, carbon steel and corrosion resistanl steel wire rope.

|

Nominal diameter of wire rope (reference) |

Minimum diameter of wire rope | Tolerance on diameter (plus only) | Allowable increase of diameter at cut end 1 | Construction | MBS composition A | MBS composition B | Approximate weight per 100 ft. |

|---|---|---|---|---|---|---|---|

| in. | in. | in. | in. |

|

lbs. | lbs. | lbs. |

| 1/32 | 0.031 | 0.006 | 0.006 | 3×7 | 110 | 110 | 0.16 |

| 3/64 | 0.046 | 0.008 | 0.008 | 7×7 | 270 | 270 | 0.42 |

| 1/16 | 0.062 | 0.010 | 0.009 | 7×7 | 480 | 480 | 0.75 |

| 1/16 | 0.062 | 0.010 | 0.009 | 7×19 | 480 | 480 | 0.75 |

| 3/32 | 0.093 | 0.012 | 0.010 | 7×7 | 920 | 920 | 1.60 |

| 3/32 | 0.093 | 0.012 | 0.010 | 7×19 | 1,000 | 920 | 1.74 |

| 1/8 | 0.125 | 0.014 | 0.011 | 7×19 | 2,000 | 1,760 | 2.90 |

| 5/32 | 0.156 | 0.016 | 0.017 | 7×19 | 2,800 | 2,400 | 4.50 |

| 3/16 | 0.187 | 0.018 | 0.019 | 7×19 | 4,200 | 3,700 | 6.50 |

| 7/32 | 0.218 | 0.018 | 0.020 | 7×19 | 5,600 | 5,000 | 8.60 |

| 1/4 | 0.250 | 0.018 | 0.021 | 7×19 | 7,000 | 6,400 | 11.00 |

| 9/32 | 0.281 | 0.020 | 0.023 | 7×19 | 8,000 | 7,800 | 13.90 |

| 5/16 | 0.312 | 0.022 | 0.024 | 7×19 | 9,800 | 9,000 | 17.30 |

| 3/8 | 0.375 | 0.026 | 0.027 | 7×19 | 14,400 | 12,000 | 24.30 |

1/ The allowable increase in diameter shall be applied to the actual diameter of the wire rope being tested.

Breaking strength of type I after endurance testing.

| COMPOSITION | A | B | |||||

|---|---|---|---|---|---|---|---|

|

Nominal diameter of bare wire rope |

Construction |

Tension load (-0,+10%) 1/2/ |

Number of reversals 3/ | MBS 4/ |

Tension load (-0%,+10%) 1/2/ |

Number of reversals 3/ | MBS 5/ |

| in. |

|

lbs. |

|

lbs. | lbs. |

|

lbs. |

| 1/32 | 3×7 | 1.0 | 70,000 | 55 | 1.0 | 70,000 | 66 |

| 3/64 | 7×7 | 3.0 | 70,000 | 135 | 3.0 | 70,000 | 162 |

| 1/16 | 7×7 | 5.0 | 70.000 | 240 | 5.0 | 70,000 | 288 |

| 1/16 | 7×19 | 5.0 | 70,000 | 240 | 5.0 | 70,000 | 288 |

| 3/32 | 7×7 | 9.0 | 70,000 | 460 | 9.0 | 70,000 | 552 |

| 3/32 | 7×19 | 9.0 | 70,000 | 500 | 9.0 | 70,000 | 552 |

| 1/8 | 7×19 | 18.0 | 70.000 | 1,000 | 18.0 | 70.000 | 1,056 |

| 5/32 | 7×19 | 24.0 | 130,000 | 1,400 | 24.0 | 130,000 | 1,440 |

| 3/16 | 7×19 | 37.0 | 130,000 | 2,100 | 37.0 | 130,000 | 2,220 |

| 7/32 | 7×19 | 50.0 | 130.000 | 2,800 | 50.0 | 130.000 | 3,000 |

| 1/4 | 7×19 | 64.0 | 130,000 | 3,500 | 64.0 | 130,000 | 3,840 |

| 9/32 | 7×19 | 78.0 | 130,000 | 4,000 | 78.0 | 130,000 | 4,680 |

| 5/16 | 7×19 | 90.0 | 130.000 | 4,900 | 90.0 | 130,000 | 5,400 |

| 3/8 | 7×19 | 120.0 | 130.000 | 7,200 | 120.0 | 130.000 | 7,200 |

1/ Tension is equal to one half the weight (w) which includes idler sheave and hanger.

2/ The magnitude of the tension loads are test parameters only and are by no means intended as design criteria.

3/ 1 cycle = 2 reversals

4/ Equal lo 50 percent of the original MBS.

|

8x7+1x9 |

||||||||||||||||||||||||||||||||||||||

|

1×7 |

|

1×19 |

|

6×7+IWS |

|

6×7+FC |

|

6×19+IWS |

|

6×19+FC |

MORE PRODUCTS

LEAVE MESSAGE

SHARE

CONTACT US

Mailbox: yunfeng@coatedwirerope.com

yunfeng@coatedsteelwirerope.com

WhatsAPP: 86+13812159799

WeChat: 86+13812159799

Cellphone: 86+13812159799

Address: No. 695, Chengshan Road, Jiangyin City Jiangsu Province,China

Copyright © 2021 JiangYin Yunfeng Steel Wire Rope Products Co., Ltd. Power by 300.cn 苏ICP备17002475号-1