CONTACT US

Please contact us through the following contact information.

E-mail:

yunfeng@coatedsteelwirerope.com

WhatsAPP:

WeChat & Cellphone:

Address:

Shanguan town, Jiangyin,Jiangsu province,China

News

Classification of nylon coated stainless steel wire rope products by twist level

- Classification:Coated steel wire rope News

- Author:

- Origin:

- Release time:2022-02-17

- Views:0

(Summary description)There are many classification methods of nylon coated stainless steel wire rope products. The common ones are classified according to the rope structure, twisting level, twist direction, use, strength and so on.

Classification of nylon coated stainless steel wire rope products by twist level

(Summary description)There are many classification methods of nylon coated stainless steel wire rope products. The common ones are classified according to the rope structure, twisting level, twist direction, use, strength and so on.

- Classification:Coated steel wire rope News

- Author:

- Origin:

- Release time:2022-02-17

- Views:0

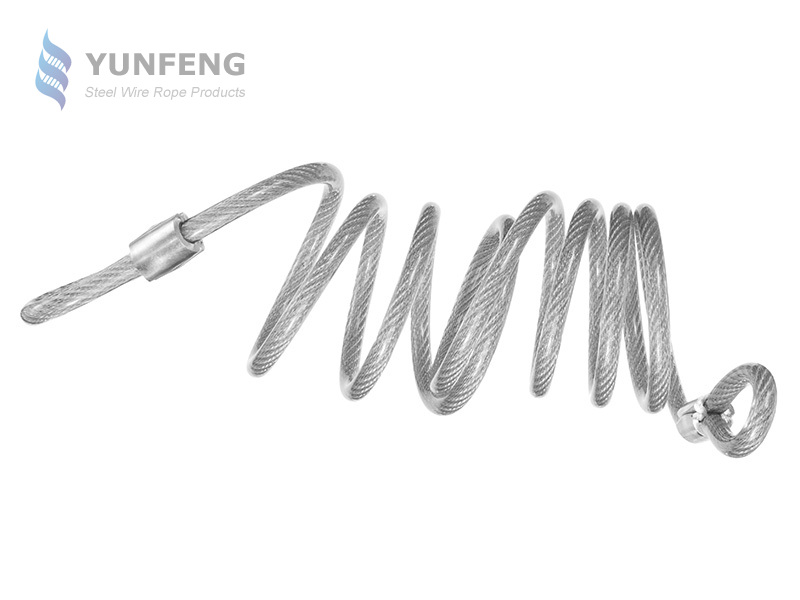

There are many classification methods of nylon coated stainless steel wire rope products. The common ones are classified according to the rope structure, twisting level, twist direction, use, strength and so on. Below, I will introduce the categories of nylon coated stainless steel wire rope products according to the twisting level.

Nylon coated stainless steel wire rope products can be divided into single-wound rope, double-wound rope and triple-wound rope according to the level of twisting.

Single-wound rope: It is made of several thin steel wires twisted around a metal core. It has poor flexibility and is easy to be worn and broken when repeatedly bent. It is mainly used as a non-moving tension cable.

Double winding rope: The steel wire is twisted into strands, and then the strands are twisted around the rope core to form a rope. The commonly used rope core is hemp core, and the metal core twisted by asbestos core or soft steel wire should be used for high temperature operation. Before rope making, the rope core is dipped with lubricating oil, which can reduce the damage caused by the friction between the steel wires. The double-wound rope has good flexibility, is easy to manufacture, and is the most widely used.

Three-wound rope: The double-wound rope is used as a strand and then twisted into a rope around the double-wound rope core.

There are two winding directions of nylon coated stainless steel wire rope products: straight winding and cross winding. The winding direction of the wire twisted into a strand is the same as the winding direction of the strand twisted into a rope, which is called a straight winding. The contact between the wires of the wire rope is good, the flexibility is also good, and the service life is long, but it has a tendency to be twisted and loosened. hoist rope or traction rope. The winding direction of the wire twisted into a strand is opposite to that of the strand twisted into a rope, which is called cross winding. The intertwined wire rope is not easy to twist and loosen, and is widely used in lifting operations.

Scan the QR code to read on your phone

Contact Us

SHARE

CONTACT US

Mailbox: yunfeng@coatedwirerope.com

yunfeng@coatedsteelwirerope.com

WhatsAPP: 86+13812159799

WeChat: 86+13812159799

Cellphone: 86+13812159799

Address: No. 695, Chengshan Road, Jiangyin City Jiangsu Province,China

Copyright © 2021 JiangYin Yunfeng Steel Wire Rope Products Co., Ltd. Power by 300.cn 苏ICP备17002475号-1