CONTACT US

Please contact us through the following contact information.

E-mail:

yunfeng@coatedsteelwirerope.com

WhatsAPP:

WeChat & Cellphone:

Address:

Shanguan town, Jiangyin,Jiangsu province,China

News

Standard for confirming the twisting quality of nylon coated stainless steel wire

- Classification:Coated steel wire rope News

- Author:

- Origin:

- Release time:2022-02-10

- Views:0

(Summary description)In the production process of nylon coated stainless steel wire, from the material selection of steel wire rope, product production, to the inspection of product elongation and fatigue, each production process must be strictly implemented according to high standards even more so.

Standard for confirming the twisting quality of nylon coated stainless steel wire

(Summary description)In the production process of nylon coated stainless steel wire, from the material selection of steel wire rope, product production, to the inspection of product elongation and fatigue, each production process must be strictly implemented according to high standards even more so.

- Classification:Coated steel wire rope News

- Author:

- Origin:

- Release time:2022-02-10

- Views:0

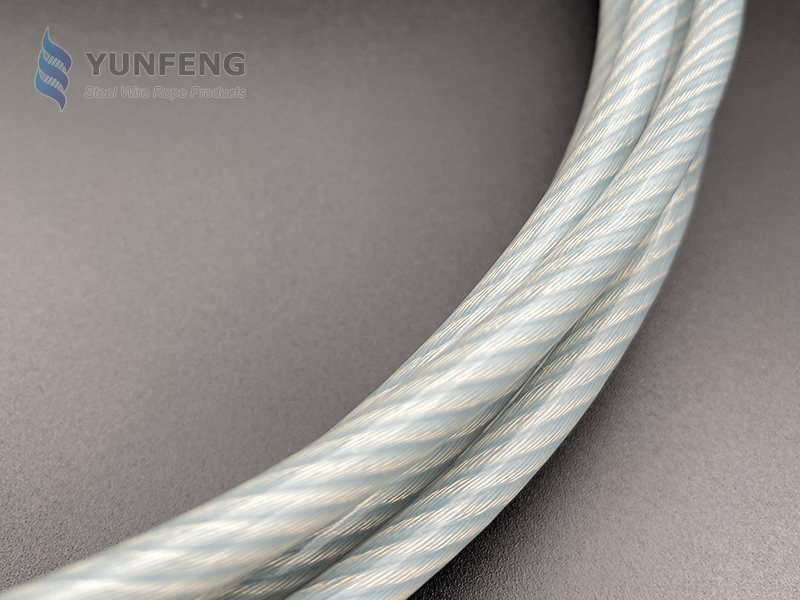

In the production process of nylon coated stainless steel wire, from the material selection of steel wire rope, product production, to the inspection of product elongation and fatigue, each production process must be strictly implemented according to high standards even more so. Then, how to determine the twisting quality of nylon coated stainless steel wire, the following is a detailed introduction for you.

The twisting quality of nylon coated stainless steel wire is confirmed from the following two aspects:

(1) Strand rope, the strand rope should be twisted evenly and smoothly, and the wires in the strand should not have broken wires, staggered, corroded and bent; Or 10m (general purpose), the steel wire joint is connected by butt welding, and the diameter of the steel wire is less than or equal to 0.6mm.

(2) Steel wire rope, nylon coated stainless steel wire should be twisted evenly, tightly, and not loose, the strands should not collapse or bulge, but allow a uniform gap between the strands, and the hemp core should not be exposed (except for the ends); stainless steel wire rope The lay length should not be greater than 7.5 times the rope diameter (6T*7+FC co-twist wire rope should not be greater than 8 times the rope diameter). The twist pitch has a deviation of not more than ±3% of the average twist pitch.

Through the above introduction, I hope to give you a reference. Manufacturers of nylon coated stainless steel wire can refer to the above standards and reject the unqualified products, so as to effectively ensure the quality of the products.

Scan the QR code to read on your phone

Contact Us

SHARE

CONTACT US

Mailbox: yunfeng@coatedwirerope.com

yunfeng@coatedsteelwirerope.com

WhatsAPP: 86+13812159799

WeChat: 86+13812159799

Cellphone: 86+13812159799

Address: No. 695, Chengshan Road, Jiangyin City Jiangsu Province,China

Copyright © 2021 JiangYin Yunfeng Steel Wire Rope Products Co., Ltd. Power by 300.cn 苏ICP备17002475号-1