CONTACT US

Please contact us through the following contact information.

E-mail:

yunfeng@coatedsteelwirerope.com

WhatsAPP:

WeChat & Cellphone:

Address:

Shanguan town, Jiangyin,Jiangsu province,China

News

Comparison of production process of manganese phosphating pu coated steel wire rope and smooth wire rope

- Classification:Coated steel wire rope News

- Author:

- Origin:

- Release time:2022-01-27

- Views:0

(Summary description)The pu coated steel wire rope is subjected to wear-resistant phosphating treatment, and a wear-resistant phosphating film is formed on the surface of the steel wire.

Comparison of production process of manganese phosphating pu coated steel wire rope and smooth wire rope

(Summary description)The pu coated steel wire rope is subjected to wear-resistant phosphating treatment, and a wear-resistant phosphating film is formed on the surface of the steel wire.

- Classification:Coated steel wire rope News

- Author:

- Origin:

- Release time:2022-01-27

- Views:0

Smooth steel wire rope production process: wire rod → pickling → water washing → zinc phosphating → water washing → drying → cold drawing → heat treatment → pickling → water washing → zinc phosphating → water washing → drying → cold drawing → smooth finish rope wire.

The above-mentioned phosphating is the surface preparation before the steel wire is drawn, and the zinc-based phosphating film is used. During the steel wire drawing process, the phosphating film is violently rubbed with the wire drawing die, and the phosphate film gradually falls off.

The pu coated steel wire rope is made of high-quality carbon structural steel hot-rolled wire rod as raw material, and it must be cold drawn to a specified diameter during production, and at the same time, it must meet certain physical performance requirements. The rope-making steel wire produced according to the above process is the smooth rope-making steel wire, and the rope-making steel wire is directly used for twisting the strand or the steel core without any surface treatment after cold drawing.

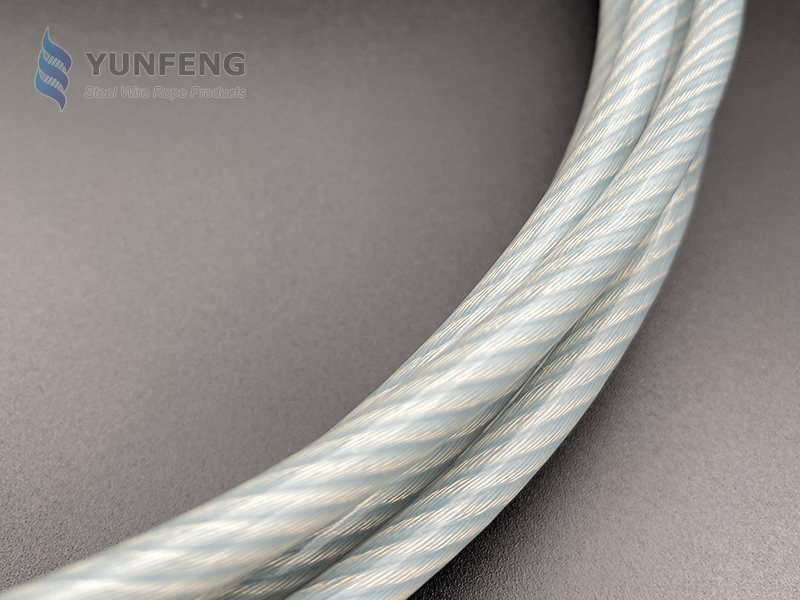

The production process of pu coated steel wire rope: smooth wire rope→alkali washing→water washing→pickling→water washing→manganese series wear-resistant phosphating→water washing→drying→twisting strands and steel core→rope closing→inspection→packaging.

The pu coated steel wire rope is subjected to wear-resistant phosphating treatment, and a wear-resistant phosphating film is formed on the surface of the steel wire. When choosing manganese-based phosphating-coated steel wire rope, it is necessary to agree with the manufacturer on the film weight range of the phosphating film, and test the film weight of the phosphating film after delivery.

Scan the QR code to read on your phone

Contact Us

SHARE

CONTACT US

Mailbox: yunfeng@coatedwirerope.com

yunfeng@coatedsteelwirerope.com

WhatsAPP: 86+13812159799

WeChat: 86+13812159799

Cellphone: 86+13812159799

Address: No. 695, Chengshan Road, Jiangyin City Jiangsu Province,China

Copyright © 2021 JiangYin Yunfeng Steel Wire Rope Products Co., Ltd. Power by 300.cn 苏ICP备17002475号-1